The tubes that pass the most stringent tests

Applications:

Telescopic cylinders, single and double acting hydraulic cylinders, immersion pumps, rollers for textile and printing machines, precision mechanical parts.

Manufacturing standards:

ASTM A 513/5

Manufacturing characteristics: The new TuffDOM line of cold drawn, stress relieved tubing has the ideal mechanical properties for fluid power and other demanding applications. TuffDOM 520 and 620 tubing are fully killed and made with exact control of their steel chemistry, thus minimizing the frequency and severuty of non-metallic inclusions. This is extremely important for optimal-quality, precision DOM tubing, which may encounter subsequent machining, centerless grinding, honing, burnishing and hard chrome plating.

Machinability tests have prooved that tools last longer and that the machinability speed is higher.

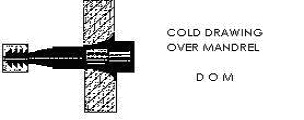

The TuffDOM tubes are manufactured by cold drawing over the mandrel ERW (electrical resistance welded) hollows and are normally manufactured according to the customers specifications.

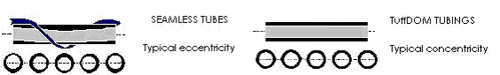

Concentricity and uniform wall are the major qualities of the TuffDOM tubes.

TuffDOM Tubing allow appreciable savings in machining costs, always joined to the highest possible quality level. Steel grades, heat treatments. surface and finishing are studied and realized to guarantee the characteristics required by the different applications.

Standard steel: Carbon:TuffDOM520

Microalloyed steels:TuffDOM620

Standard supply conditions: BK+S (stress relieved annealed)

Size range: See table

Lengths: Up to 11500 mm

Controls and tests: Visual, dimensional, eddy current 100%

Certificate: According to international standards

Packaging: In bundles

On request: INSIDE HONED TUBES TO H9

OUTSIDE HONED and/or GROUND TUBES

HARD CHROME PLATED TUBES